RECOMMENDED VIDEOS

Tokyo Metropolitan Government (Asian Network of Major Cities…

Tokyo Metropolitan Government

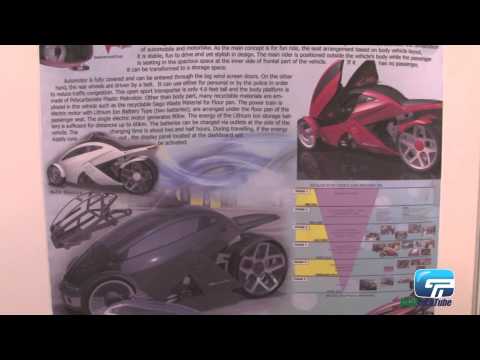

University of Sarawak - Research & Development : Automotor

Centre of Excellence for Renewable Energy (CoERE), Universiti Malaysia Sarawak

FirstCarbon Solutions - Run your business. Leave Sustainability…

FirstCarbon Solutions, Philippines

Tokyo Metropolitan Government, Bureau of Sewerage : Sewerage…

Tokyo Metropolitan Government, Bureau of Sewerage

Tokyo Metropolitan SME Support Center : Supporting SME…

Tokyo Metropolitan SME Support Center

Related Stories

IE Expo 2021: South China's Leading Trade Fair for Environmental Technology Solutions

IE Expo 2021: West China's Leading Trade Fair for Environmental Technology Solutions

IE Expo 2021: Asia's Leading Trade Fair for Environmental Technology Solutions

IE Expo 2020: Trade Fair for Environmental Technology Solutions

IE Expo 2020: Asia's Leading Trade Fair for Environmental Technology Solutions

12 Feb, 2018

London store recycles 60,000 plastic bottles for 3D-printed interior

Others | UNITED KINGDOM | 08 Jan, 2018

Published by : Eco Media Asia

You can tell that Bottletop, a “sustainable luxury” brand that transforms castoff materials into chic carryalls, takes its zero-waste philosophy to heart. Case in point? Its new flagship store on London’s Regent Street, which boasts a 3D-printed interior derived almost entirely from recycled plastic bottles. Together with Krause Architects and Ai Build, Bottletop conscripted a troop of Kuka robots to print sections of the boutique using a filament made from plastic waste gathered from the streets Delhi in India.

There’s a social component to the process, too. ReFlow, the Netherlands-based company that makes the filament, says it reinvests part of its profits into local manufacturing projects.

“Our mission is to significantly improve the lives of the nearly 40 million waste collectors worldwide who earn less than $2 a day and to create a global, socially responsible 3D-printing community,” ReFlow says on its website.

Inspired by the work of Paolo Zilli, a senior associate at Zaha Hadid Architects, the Bottletop store is a “world-first in retail” that “contributes to a broader positive ecosystem, in line with the values … of sustainable luxury, ethical design, technical innovation, and cross-cultural collaboration,” the company says in a statement.

The recycled plastic isn’t the store’s only sustainable element, either. Look down and you’ll find that the flooring is composed of recycled rubber tires; glance up and you’ll discover a canopy made up of thousands of used metal cans suspended within a 3D-printed filigree.

The store is a work in progress—literally. The KUKA robots are still hard at work producing whole segments, meaning that the space will evolve over time. You can even take home a piece of the store, in a manner of speaking: For a limited time, customers will be able to employ an on-site robot to print personalized bag charms using the ReFlow filament.

“For the first time, visitors to our store will be able to witness the sustainable use of this technology first hand while shopping the Bottletop collection and learning about the mission of the brand,” the company says. “This is so exciting for us as our customers can watch the transformation of the store.”

Article from inhabitat.com

by Jasmin Malik Chua